Shindengen Electric Manufacturing Co., Ltd. has launched the LF Dual Series MOSFET for various types of automotive ECU.

This series maintains the low dissipation and large current characteristics of Shindengen’s conventional products, but features 2 elements in a single package, which allows for it to contribute to downsizing and reduction of the number of components in a variety of applications including automotive motor drive, engine ECU (injector drive), reverse connection and reverse current prevention relays, and more.

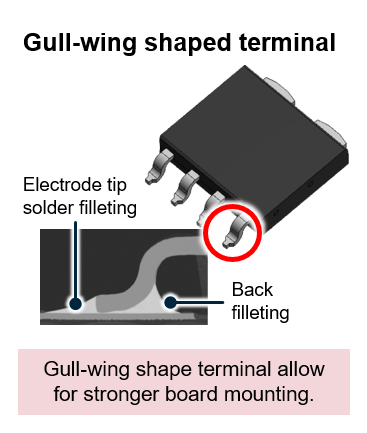

In addition, the series also utilizes gull-wing shaped lead terminals to achieve high reliability mounting for automotive applications.

We are currently shipping samples of this series with mass production expected to begin in December 2021.

■ Overview

In the face of stronger regulations resulting from decarbonizing and other environmental concerns, there has been a rapid acceleration in the electrification of vehicles and in automated driving, which has in turn resulted in a dramatic increase in the number of semiconductors installed in a single vehicle. There is demand for these semiconductors to have low dissipation and large current, while downsizing circuits and reducing the number of components through higher efficiency.

Shindengen is launching the AEC-Q101 automotive reliability standard compliant, 40/60V withstand voltage, compact, low ON resistance LF Dual Series 2 element power MOSFET in order to satisfy this growing market demand.

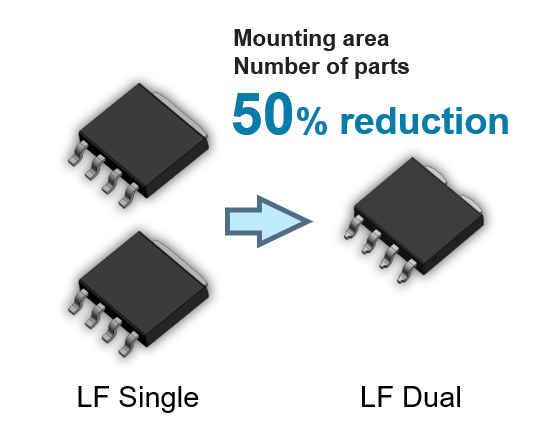

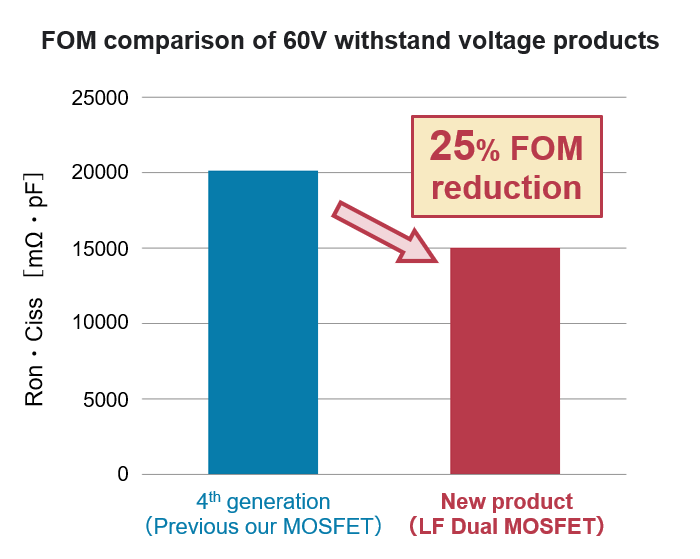

This series further improves characteristics from the 4th generation power MOSFET (EETMOS 4) which when combined with Cu clip connections with low electrical resistance and high heat dissipation, reduce the figure of merit (FOM); which is the product of the ON resistance and total gate load, by 25%. Incorporating 2 of these elements in a compact package reduces both mounting area and number of components by 50% compared to use of packages with only 1 element, which contributes to circuit downsizing and weight reduction.

In addition, the use of the wettable flank structure improves wettability visibility, use of plated package lead tips improves solder wettability, and the use of gull-wing shaped lead terminals realizes the strong solderability required for in-vehicle board mounting, which all combine to make high reliability mounting possible.

■ Features

Two low dissipation power MOSFET elements in 1 package

Allows for a reduction in mounting area and number of components compared to use of two 1 element devices.

New structure further improves characteristics from the 4th generation power MOSFET

Reduction of capacity from Shindengen conventional products reduces FOM (Ron×Ciss) by 25%.

This contributes to a reduction in switching loss.

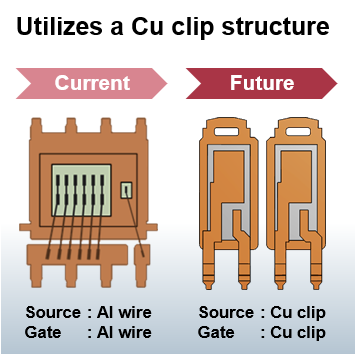

Utilizes a Cu clip structure

Achieves downsizing and reduced ON resistance through a substantial shift to low resistance and improved heat dissipation.

Gull-wing shaped lead terminals

Alleviates substrate stress while the wettable flank structure improves wettability visibility to provide higher reliability.

Can be used to replace existing packages

Similar external size and shape to SOP8 and HSON series packages allows for easy replacement.

AEC-Q101 compliant / Tch=175℃ guaranteed

For More Detail,

Reference to Original Web Site:

https://www.shindengen.com/products/new/2021/mosfet_lf_dual.html